EO is the most popular and growing slightly because it is the most material friendly.

As devices get more complex (e.g. combination products, custom kits, others), they may be made of multiple materials, some of which may not be compatible with radiation. EO can also be used in some instances where products contain computer chips as they will not affect their performance, whereas radiation processing will generally not work for these items. One of its main historical drawbacks is that it typically had the longest turnaround time as compared to radiation processing. However, with the advent of things like combining All-In-One processing with parametric release, the turnaround time, where this can be used, rivals that of the radiation techniques.

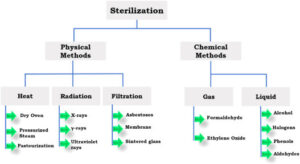

Moist heat (steam) sterilization is arguably the best method of sterilization since it is the least expensive, requires the lowest capital investment for the equipment, non-toxic to workers, leaves no residue, and the fastest method. However, due to the high temperatures required, many materials cannot tolerate this technique so these products have to use some other sterilization method.

Peracetic Acid (PAA) can be done at room temperature, which has some advantages for products that are temperature sensitive. In is a vapor formed by a reaction of acetic acid and hydrogen peroxide, with the addition of a catalyst. The compounds exist in equilibrium and once the compound decomposes, the byproducts are oxygen, carbon dioxide, and water. During sterilization the vapor interacts with bacteria’s cellular constituents, breaking them down and inactivating routine functionality. The vapor process is effective against all types of microorganisms.

[If you’re doing to include PAA here, which is a good idea, you should also have a short paragraph here about NO2 or it may look like you are biased and/or playing favorites. You might be able to pull the information you need for this off of the Noxilizer website, or you could contact someone who works there and ask them.]